- DIE FASER.

EXTRO ASPHALT FIBER

renewable raw material - homogeneous product - consistent quality

THE BHS - EXTRO ASPHALT FIBRE

- Wood fibres - patented - extruded and pelletized

- extracted from softwood cuttings

- Moisture-resistant and fast dissolving due to special emulsion

- Dosing via existing technology - delivery in big bags

PHYSICAL AND CHEMICAL PROPERTIES

SOURCE RAW MATERIAL:

- Max. fibre length: 3 mm

- Max. Fiber thickness: 0.05 to 0.5 mm

PELLET

Fiber content: 95 %.

- Bulk density: 0.50 to 0.60 g/cm³

- Diameter: approx. 6 mm

- Length: 5 to 10 mm

- Dosing: 0.3-0.5 % depending on the type of rock and grain size

- As with all natural products, the values may vary slightly.

- Normal mixing time for Stone Mastic Asphalt (SMA)

- permanent bitumen binding beyond installation

- developed in cooperation with the Leibniz-Institute for Agricultural Engineering Potsdam-Bornim in cooperation with many years of research.

- independently tested by HTW Dresden

SCRUTINY

The University of Applied Sciences Dresden (HTW), Department of Road and Civil Engineering - Prof. Dr. -Ing. Volker Rauschenbach, has tested the extro asphalt fibre.

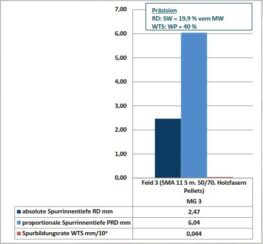

EXCERPTS OF THE RESULTS

SUMMARY OF THE RESULTS

In preparation for the market launch of a natural pine fibre product as a binder carrier, it was necessary to demonstrate its equivalence with a cellulose fibre used in practice on the basis of the study programme.

The available results show that the different types of stabilizing additive are to be considered equivalent. It is possible to replace conventional cellulose fibres as binder carriers with natural fibres.